UNPARALELLED PROTECTION

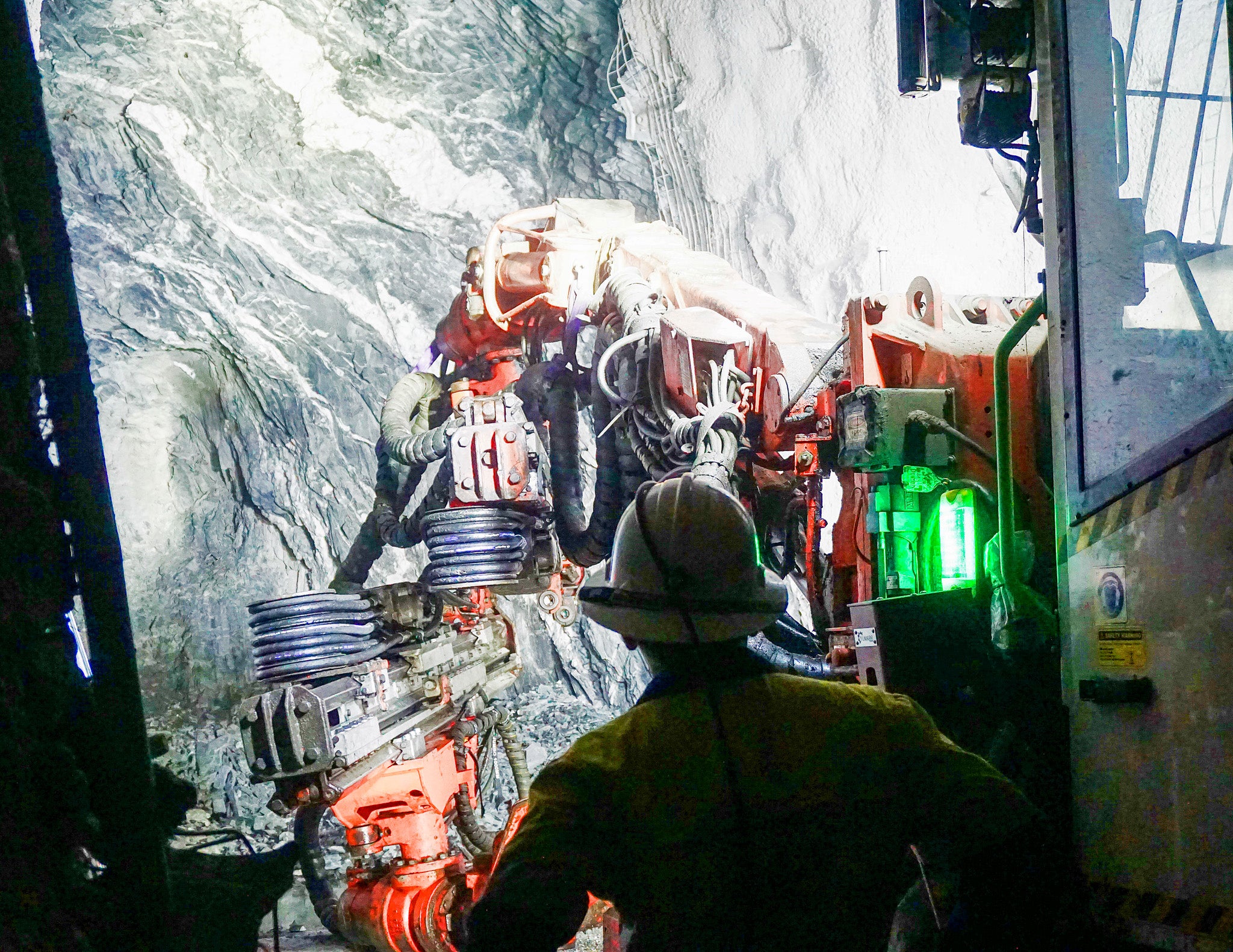

JumboGuard uses advanced detection, tracking and classification algorithms enabling the system to find persons in the presence of disturbances like spray & dust. This is the key to reliably isolate the boom and to prevent false triggers.

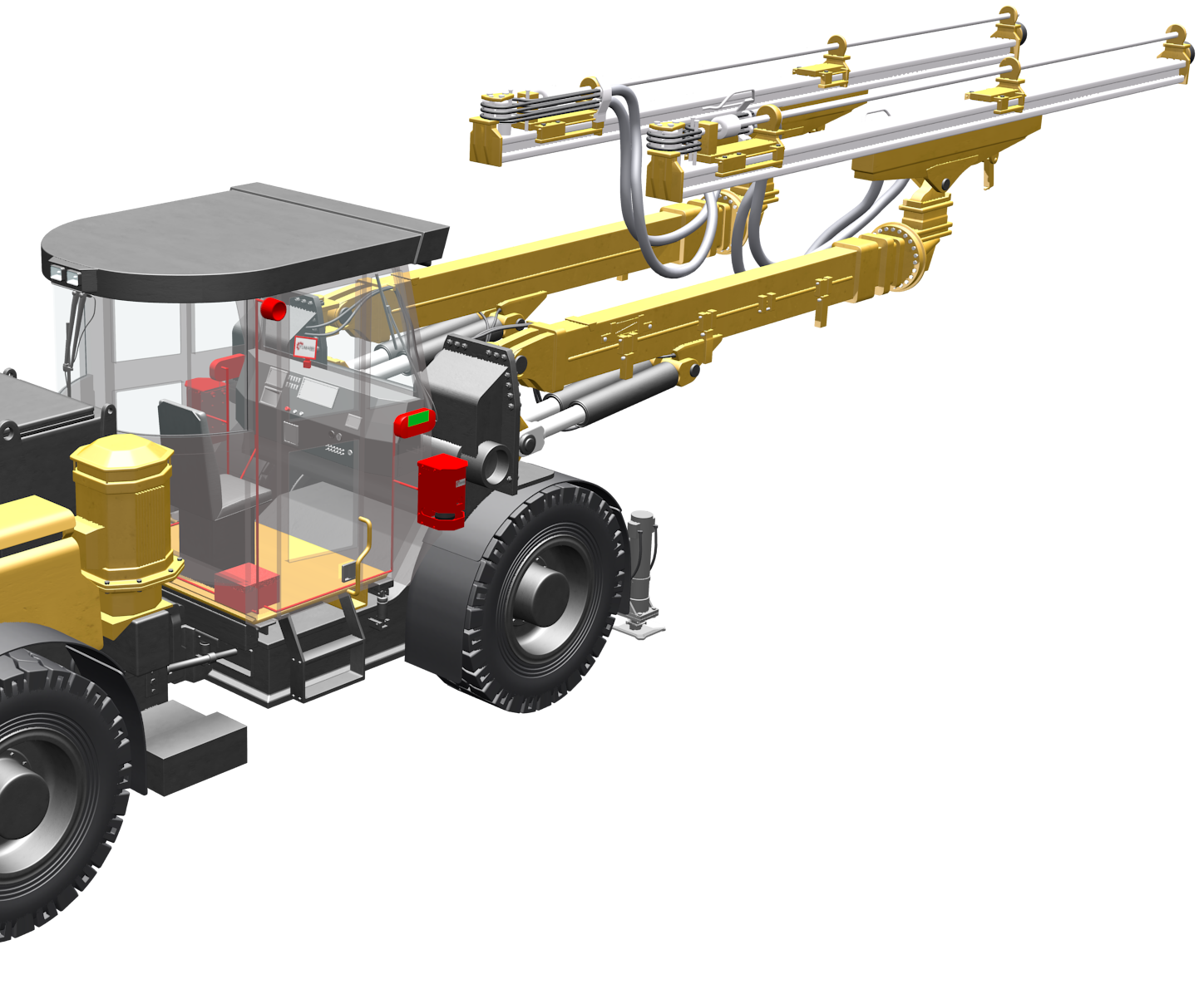

Two laser sensors continuously scan the left and the right-hand side of the drill rig. The surrounding area is divided into a safe working area (home zone) and the boom operating zone (danger zone). An automatic mapping algorithm finds the contour of the tunnel wall. This boundary is used as a perimeter for the home and danger zone, which recalibrates automatically and dynamically as the vehicle moves.

JumboGuard always starts in a safe state with the hydraulics being isolated. This prevents unintentional start of the drill and boom movement. Release of the drill hydraulics is only allowed if the danger zone is free. For that reason, the system utilises a person counting algorithm for the danger zone entry and exit on both sides. Every person walking into the zone increases the counter. When a person returns into the home zone the person counter decreases.

LAYERS OF SAFETY MECHANISMS

Releasing the booms utilises a manual “Confirm” push button as an essential safety feature to enable the operation after hydraulic isolation. This is an active operator acknowledgement to confirm, that the danger zone is free after the detected return of any personnel.

The machine crew knows at any given time the state of the hydraulics, which is indicated by means of audible signals as well as traffic light LED’s.

Essential information is displayed on a small ruggedised operator touch display inside the operator cabin. As the system continuously performs a self-check procedure, this panel also provides diagnostics information for maintenance.

YUMARR offers different system variants under the “JumboGuard” system family to accommodate individual mine site safety requirements and machine types.

BENEFITS

- Eliminate the risk of "human factor" to not isolate the booms

- Eliminate the risk of entanglement when releasing the booms using audible "release warning" and "release delay" signals

- Safe Start-Up: booms are isolated initially. The operator must confirm to start the operation

- Peace of mind: "Best Practice" safety measures have been implemented for underground drilling operations

JumboGuard, which has been described as a breakthrough safety system for underground mines, has won several prestigious awards for YUMARR Automation and has already proven effective at mines in Western Australia, South Australia, New South Wales and the Northern Territory.

Credit Card Payments: To pay via credit card, simply get in touch with our sales team via phone or email to arrange a secure payment.

Click Here To Download Brochure