QUALITY ASSURANCE YOU CAN TRUST

We take pride in our systematic approach to ensuring client satisfaction and quality assurance on every project by providing:

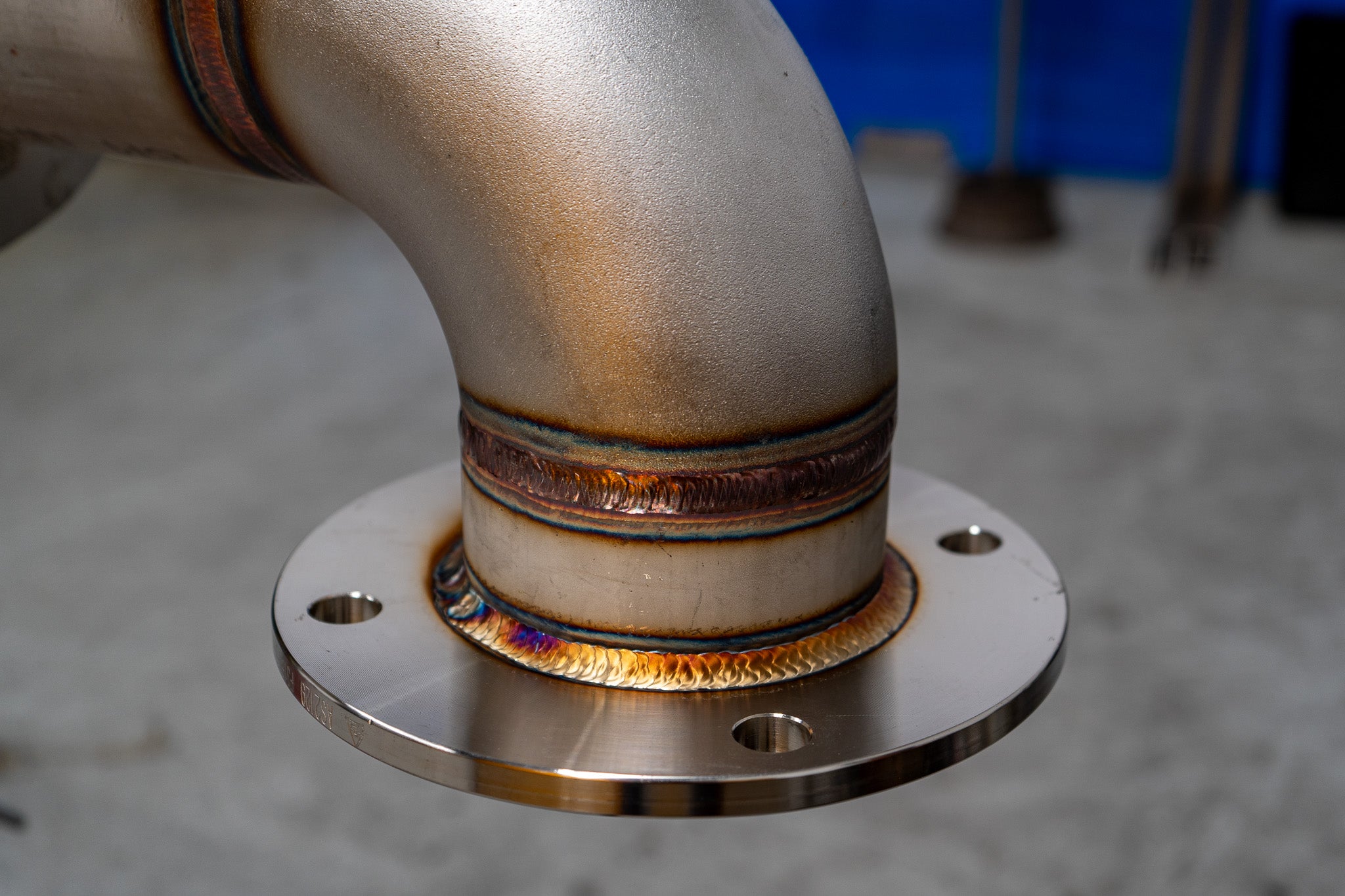

- Welding Procedure Specification (WPS)

- Procedure Qualification Records (PQR)

- Full traceability with Manufacturers Data Record (MDR)

- Project-specific Inspection Test Plan (ITP)

- Adherence to Quality Management Standard (QMS) ISO 9001.

Murray Engineering also provides a full range of testing procedures including hydrostatic testing, plus other non-destructive examination methodologies including Visual scanning (VS), visual examination (VT), dye penetrant (DPI), magnetic particle (MPI), ultrasonic (UT) and radiography (RT).

We also provide pickling and passivation services with TIG Brush and full- submersion methods to ASTM A380 standards for all external and internal surfaces.

This ensures not only unparalleled day-to-day reliability and safety, but also pipework dependability, durability, and longevity.

Murray Engineering provides pipework in all size requirements from DN15 to DN1000, in materials including carbon, stainless, duplex and super-duplex steel options (316SS, SAF2205, SAF2507).

All work, including procurement of materials, fabrication, inspection and testing adhere to the relevant Australian standards.

With a proven track record servicing some of the biggest brands across mining and industry, Murray Engineering is a world-class provider focused on delivering value to clients into the future.

Contact us today to discuss your exact requirements.