1

/

of

1

Murray Engineering

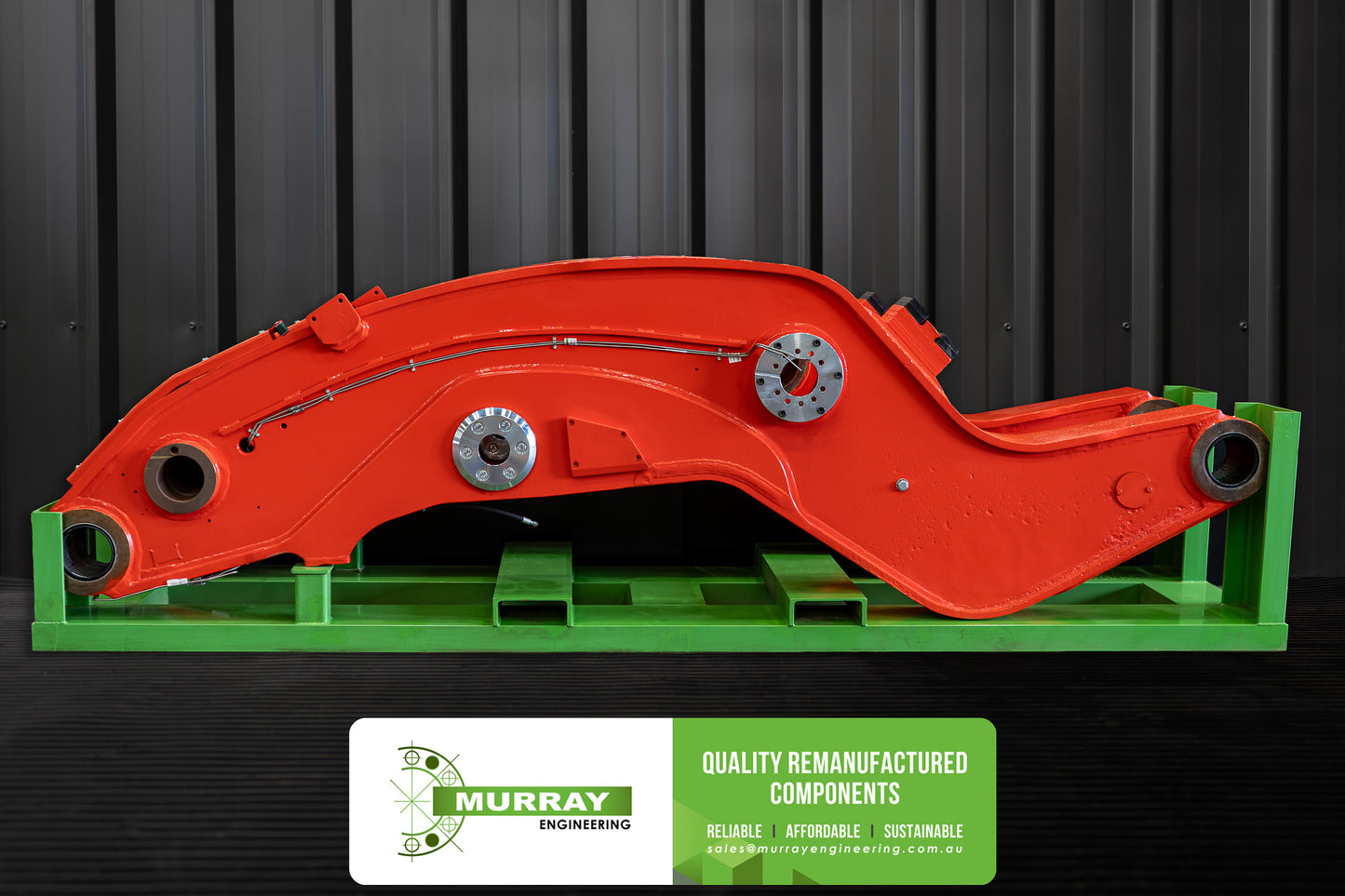

Sandvik LH621i Lift Arms

Sandvik LH621i Lift Arms

Couldn't load pickup availability

Murray Engineering’s service exchange components are purpose-built to help you minimise downtime and control maintenance spend — without cutting corners on quality. With fast access to critical parts and components rebuilt to exceed OEM standards, we’ll help keep your loader in the dirt and out of the workshop.

The Sandvik LH621i lift arms connect the loader’s frame to the bucket and support heavy lifting. They provide the leverage needed for loading and dumping operations.

Sandvik LH621i Loader Technical Snapshot

- Smart Control Systems: Includes Sandvik Intelligent Control System and My Sandvik Digital Services for real-time monitoring and diagnostics.

- Automation-Ready: Fully compatible with AutoMine®, allowing quick integration for autonomous operation.

- Engineered for Performance: Available with a 352 kW Tier 2 engine or a low-emission 375 kW Tier 4 Final engine.

- Operator Safety & Comfort: ROPS/FOPS-certified cabin with noise suppression and an intuitive 18 cm touchscreen interface.

- Easy Maintenance: Ground-level service access for reduced downtime and improved fleet availability.

Why Miners Choose Murray Engineering for Service Exchange Components

- Reliability – Every component is stripped, rebuilt, and rigorously tested in-house to meet or exceed OEM standards, so you can install with confidence and keep machines running.

- Affordability – Cut maintenance budgets by up to 60% compared to buying new, without compromising on safety or performance.

- Speed – Our extensive inventory and quick turnaround times mean the parts you need are ready when you need them — helping you avoid costly hold-ups